Glass and acrylic are the two options when it comes to making see-through swimming pools. People often confuse the two, as acrylic is commonly known as Plexiglass, Lucite, or Lexan - common brand names for PMMA plastic. In this article, we will discuss glass and why it's not typically used for pools compared to acrylic.

Glass:

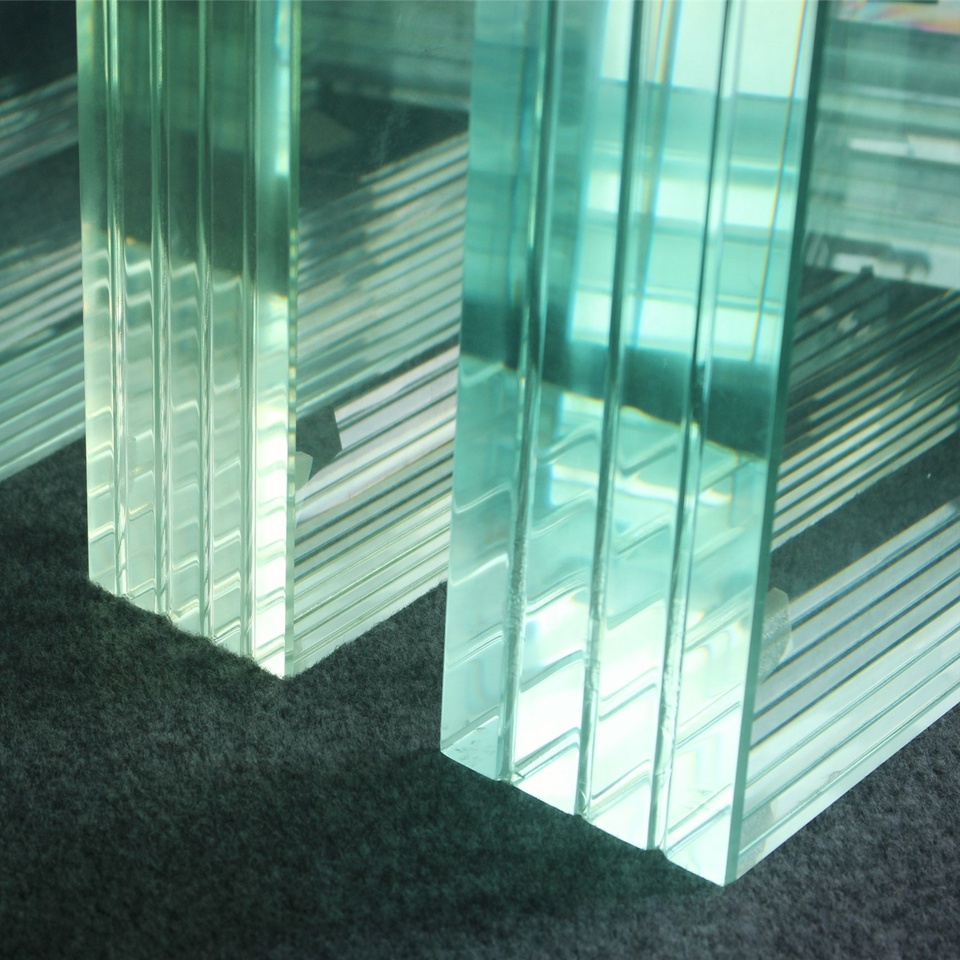

Glass is a popular building material due to its many benefits and relatively inexpensive production costs. It's used for most buildings, alongside our own pool walls. Glass is extremely rigid, making it very scratch-resistant and strong for outdoor use. Our pool glass is typically a 3/4-inch sheet layered with special glue that does not come apart or allow any discoloration. We use tempered low iron glass with about 91% transparency, compared to regular glass with 83% light transmittance.

Acrylic:

Acrylic is a synthetic material used in various applications, including building construction, automotive manufacturing, and household items. Acrylic is known for its transparency, durability, and versatility. It is more transparent than glass and does not have any hues. The refractive index for acrylic is similar to water, providing a perfect view into your pool.

In building construction, acrylic is often used as a substitute for glass due to its strength and durability. Acrylic sheets are lighter and more impact-resistant than glass, making them ideal for use in areas where safety is a concern, such as holding in large volumes of water.

Downsides:

For most of our clear pool builds, we do not use glass, and the primary reason is the way the materials behave. Glass is very rigid, which does not make it a good option for dynamic loads like water that tends to mold the material over time. This is why we have a 7-foot length and 2-foot height limit for our glass builds for safety reasons. Glass is also heavy, making it harder to install and ship. Any chips, cracks, or damage can happen during transportation, making it riskier to ship than acrylic. Often times, there is damage to the glass that would require a new panel to be placed. Chipped glass is not repairable and will only worsen over time with the dynamic load of water. Our acrylic is made with virgin Lucite® that we mold and add our special UV-inhibiting formula, warrantied up to 20 years for yellowing and brittling. Our acrylic has an average clarity of above 93%, while regular glass is closer to 83%.

Benefits:

The two main benefits of glass are its price and scratch resistance. When it comes to manufacturing custom acrylic panels, costs can be significantly higher compared to layering glass sheets that are already made. Another benefit is the actual lead time. Our glass panels take on average 2-4 weeks to manufacture and deliver, while our acrylic panels can take up to 6-10 weeks. Glass is very scratch-resistant due to its rigidity, while acrylic is softer and can be scratched. However, acrylic is easily repairable, unlike glass.

Conclusion:

Glass is an amazing material that is cheap, easy to make, and scratch resistant. There is a time and place for a glass pool but the overall choice is to stick with Acrylic for pools, but with certain clients choosing the look and scratch resistance of glass. At the end of the day we focus on safety and acrylic is the safer choice although more expensive.

References:

-

El-Sayed, M. A. (2012). Handbook of industrial refractories technology. Elsevier. https://doi.org/10.1016/B978-0-12-385971-3.00011-9

-

Hoskins, R. J., & Koval, J. C. (1999). Materials science for engineering students. CRC Press.

-

Lim, J. J., & Tan, M. J. (2011). Mechanical properties of polymethylmethacrylate (PMMA) acrylic bone cements containing bioactive glass. Journal of the Mechanical Behavior of Biomedical Materials, 4(8), 1737-1747. https://doi.org/10.1016/j.jmbbm.2011.06.009

-

Munk, P., Boegh, E., & Strobel, B. W. (2005). Visualization of water in plants using NMR imaging. Progress in Nuclear Magnetic Resonance Spectroscopy, 47(2), 79-103. https://doi.org/10.1016/j.pnmrs.2005.04.001

-

Rajendran, S., & Ravi, V. (2016). Polymethylmethacrylate: A review of the material and clinical aspects. Indian Journal of Dental Research, 27(4), 487-496. https://doi.org/10.4103/0970-9290.191893

- Delbeek, J.C. and Julian Sprung. The Reef Aquarium: A Comprehensive Guide to the Identification and Care of Tropical Marine Invertebrates. Ricordea Publishing, 1994.

- Krambeck, L. Aquarium Design: The Comprehensive Guide to Stunning Aquariums. Aquarium Design Publishing, 2017.

- Ridgway, S. A., & Harrison, L. R. (2002). The use of acrylic sheet for marine aquaria. The 9th International Conference on Polymers and Organic Chemistry, 2002, 77-83.

- Thiel, W. Acrylic Sheets in Aquariums. Reinhold Publishing Corporation, 1962.

0 comments